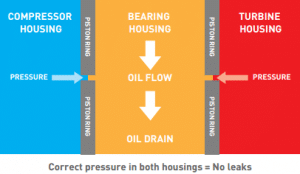

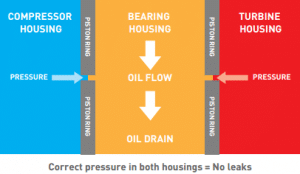

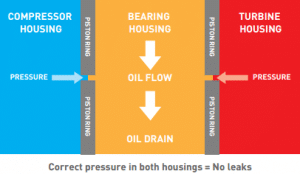

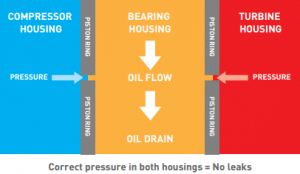

If any one part of the seal assembly is faulty it can have adverse effects on the other parts in the ‘seal assembly’. For example, a piston ring and flinger bore can be geometrically correct, but oil leaks still occur on the compressor side. This is because the third piece of the puzzle, the pressure, is not correct. If the original cause of failure is not identified it is likely the same type of failure will occur on the remanufactured turbo.

Oil leaks can cause catastrophic damage to the bearing systems and occur within seconds of the turbocharger commencing operation. To help you identify and prevent oil leaks from reoccurring when carrying out a repair, we have highlighted some of the main causes and the signs of oil leaks.

Causes Of Oil Leaks To The Compressor Outlet:

- Blockages or restrictions to the air intake pipe, hose or filter can create a vacuum, causing oil to leak into the compressor housing;

- Air leaks in the intake hoses or at the intercooler.